How to build a hydraulic cylinder. In hydraulic cylinder oil ports are provided to feed pressurised oil.

7 Important Hydraulic Cylinder Parts Their Names Functions Diagram

Gradually pump the hand pump while observing the pressure gauge.

. The hydraulic press having a working pressure of water as 16 Nmm 2 and exerting a force of 80 kN is required to press materials upto a maximum size of 800 mm 800 mm and 800 mm high the stroke length is 80 mm. A tube with finished interior and hard chrome-plated piston rods used to prevent pitting and scoring A piston and ram Two end caps. Generally they are made to fit nuts 2 to 6 inches in diameter and reversible to match 14 inches to 516 inches- click on through to the merchandise page for more descriptive specs.

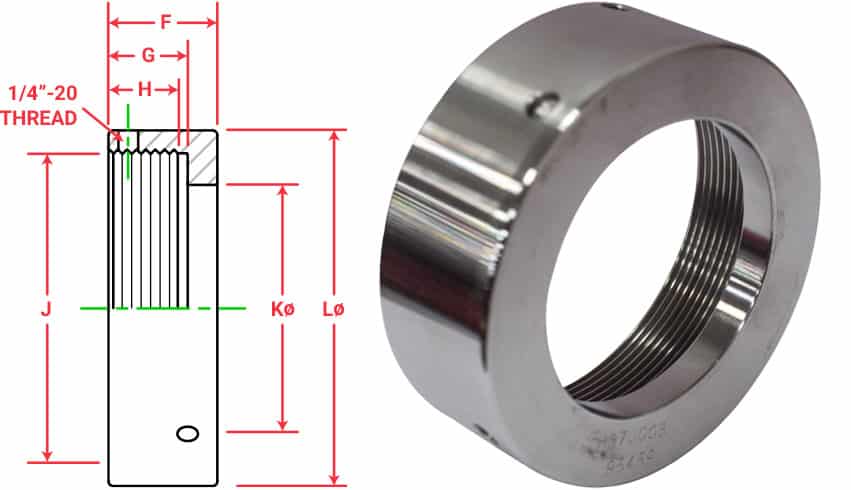

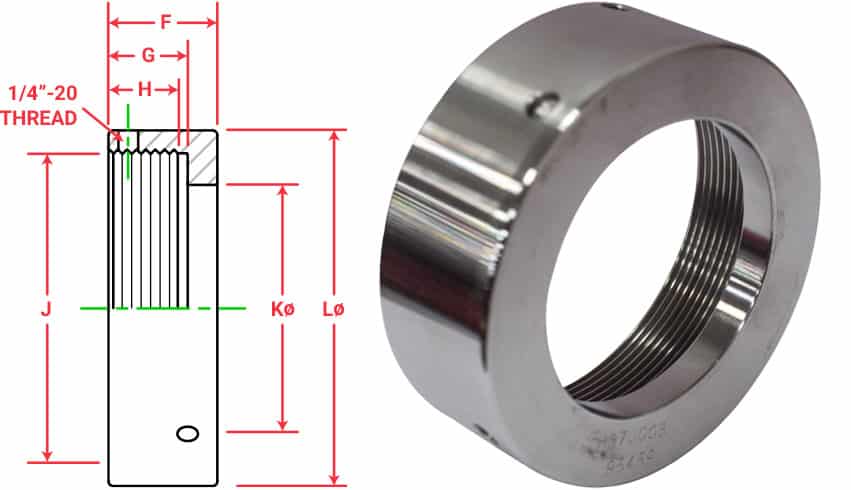

You often ask me about the cost of a given project so the list is listed below. Chief Screw-In Glands 3000 PSI Series. In some cases especially in small hydraulic cylinders the rod gland and the bearing elements are made from a single integral machined part.

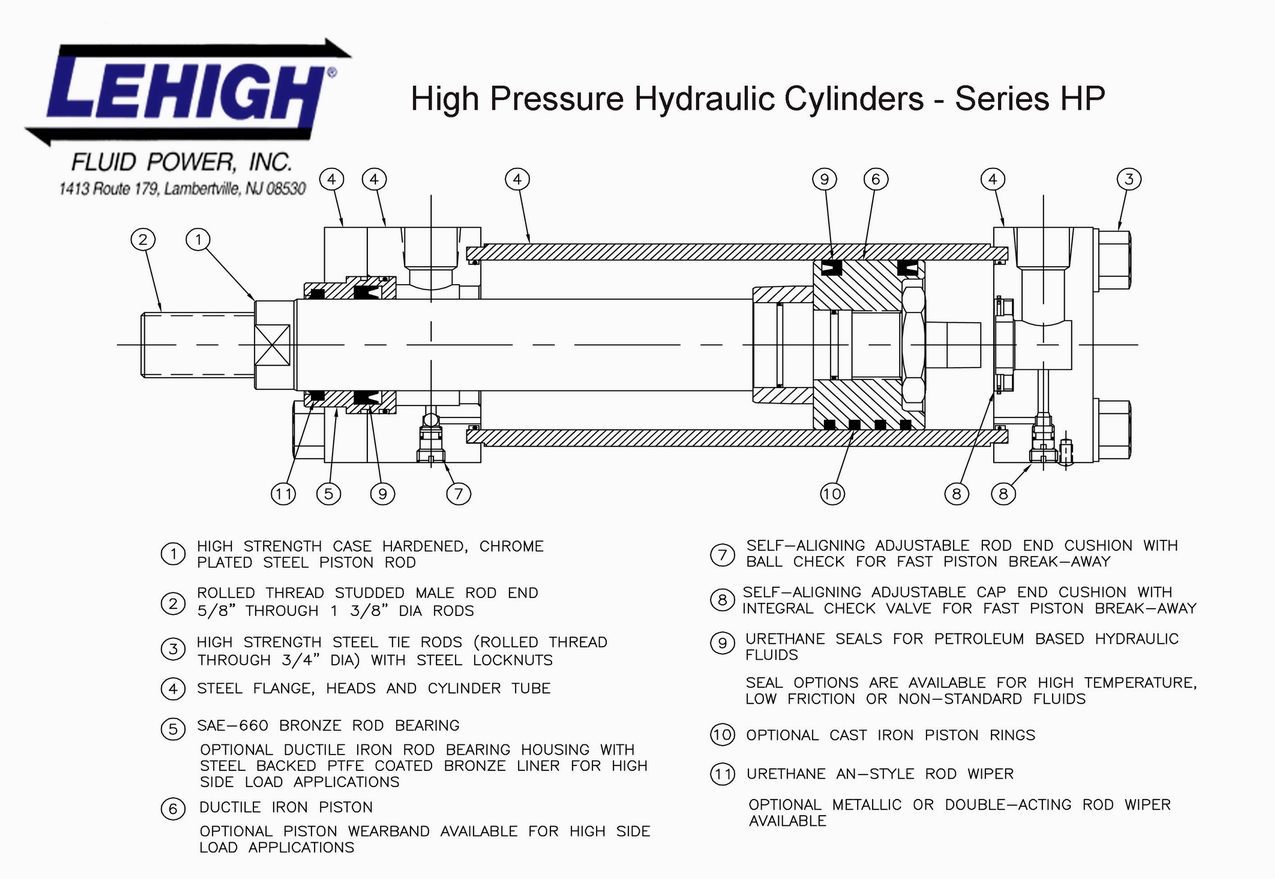

In the light of the special working condition of the excavator hydraulic cylinder seal structure the buffer structure mechanical structure and coating technology for a lot of research work yuan xing for construction machinery manufacturers all over the world each year hundreds of thousands of high quality excavator hydraulic cylinder. Hydraulic cylinder design can include many components including. Chromed grounded polished piston rod will operate at full pressure through 16 stroke.

The cylinder is first designed by a team of hydraulic cylinder engineers taking into account the use of the hydraulic cylinder and the environment that it will be in. Fill the cylinder through the cap-end port with hydraulic oil. There are primarily two styles of hydraulic cylinder construction used in industry.

AAA Engineering is known worldwide for delivery excellence in the field of engineering consulting services. The advantage of a seal gland is easy removal and seal replacement. Given that the Hydraulic press will work.

Calculate the number of thread required to takes the full load coming on end-plug. Pins clips cotters included. First end-plug is threaded and fitted in cylinder then welded.

Criteria for selection of value of these figure we have discussed in study of Guide-bush. Hydraulic cylinder gland design Description. This dictates materials coatings seals and other specialist parts.

Keep on pumping until the rodgland is pushed completely out of the cylinder tube. Fluid in the rod end of the cylinder is exhausted out of the rod-end port. Load on end-plug W 0785xdi²xp Load on end-plug is support by threads.

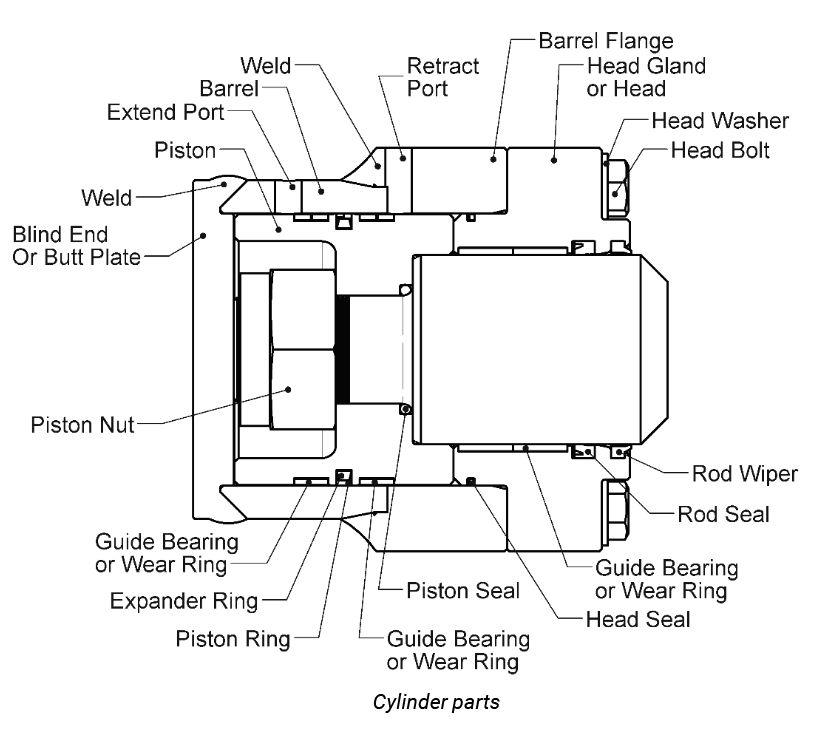

The barrel is closed on one end by the cylinder bottom also called the cap and the other end by the cylinder head also called the gland where the piston rod comes out of the cylinder. Hydraulic Cylinder for Safety Locks of Jacks and Lifts. The sealing system comprises a gland often called a packing box usually containing two or more primary and secondary sealing elements in order to contain the pressurized hydraulic fluid typically max.

Used at high pressures hydraulic cylinders produce large forces and precise movement. Bleed off port check valve end plug gland bush guide bush lock nut main shell o-ring oil port for forward oil port for return piston piston rod piston seal rod rod seal gland seal seal plate sleeve guide collar guide stopper tube stroke of cylinder tapper end. Hydraulic systems are designed in compliance with any external legislation that relates to the industry that it is being designed.

In todays article guide I will try to explain the construction of the actuator. 2 thickness of gland-bush is also calculated by using same imperical formula described for Guide- bush. Two Stage Telescopic Cylinder 233 Inch Stroke.

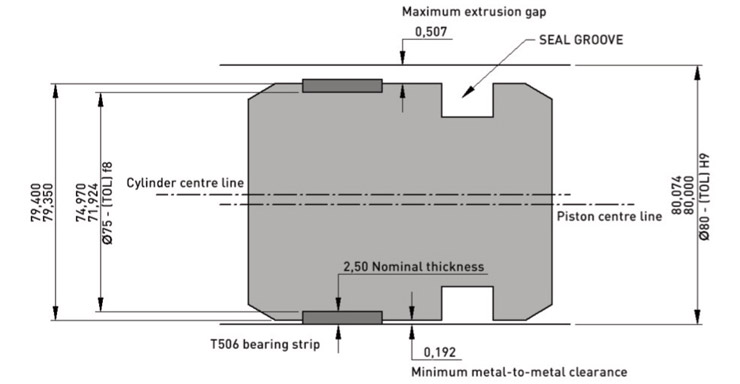

The piston has sliding rings and seals. This area is called the seal gland. Design and draw the following parts of the press.

It may be threaded or bolted type and its size depends on the flow of oil thought these oil ports and inside diameter of cylinder 138. Double-acting cylinders have ports at both cap and rod ends. The manufacturing of hydraulic cylinder requires many components.

Connect a 300-psi mechanical hand-pump with pressure gauge to the closed-end port. The seal gland contains a primary seal a secondary seal buffer seal bearing elements wiper scraper and static seal. The piston divides the inside of the cylinder.

They are therefore constructed of strong materials such as steel that is capable of withstanding the large forces involved. The rodgland assembly should begin to move. The cylinder is extended by pumping hydraulic fluid into the cap end of the cylinder which moves the piston and rod.

A hydraulic cylinder is a linear actuator that helps in generating an automatic force in a straight line either by pulling or pushing. In other word we can say a hydraulic cylinder is a device which converts the energy of fluid which is in a pressure form in to linear mechanical force and motion. Tie rod and welded body cylinders.

Hydraulic cylinder gland seal from Dms Seals Technology Check it. Typical cylinder design and sealing systems are indicated in Figs 161 and 162 respectively. 8-40 Design of Hydraulic Cylinders Where w force action on gland-bush.

Reversing the flow of oil through the cylinder retracts the cylinder rod. DMS SEALS TECHNOLOGY COLIMITED Site map The Professional Sealing Solution SupplierO Ring Suppliers Oil Seal Manufacturers. Unfortunately as in the previous project I had a lot of problems due to the lack of friends who would be in the subject.

Urethane u-cup urethane wiper in gland. Ductile iron piston butt gland and clevis. 210 bar inside the cylinder.

These are circular or rectangular rings threaded and welded to the outside diameter of cylinder tube. Adjustable gland nut wrenches are engineered to match and use hydraulic cylinders typically in construction and farm equipment scenarios. Beyond this other broad types of cylinder design include.

3 Force acting on gland-bush is equal to projected area of hydraulic seal multiplied by working pressure. Ø110x130 L550 - 400 PLN. W dt x 314 x Pt x n x fs 8-26.

The hydraulic cylinder consists of a cylinder barrel in which a piston connected to a piston rod moves back and forth. The hydraulic cylinder is a positive displacement reciprocating hydraulic motor which convert the energy of a fluid into the kinetic energy of the moving piston.

Sae 1050 Sae 1040 Quality Grade Steel Hydraulic Cylinder Gland

Hydraulic Cylinders Lehigh Fluid Power

Gland 3d Cad Model Library Grabcad

Th Gland Cap Head Nut Hydraulic Cylinder Component Parts

The Function Of Hydraulic Cylinder Seals Custom Hydraulics Design

Bringing Reliability To High Pressure Hydraulic Cylinders Fluid Power Journal

O Rings O Yeah How To Select Design And Install O Ring Seals Tarkka

0 comments

Post a Comment